Project Description

Description

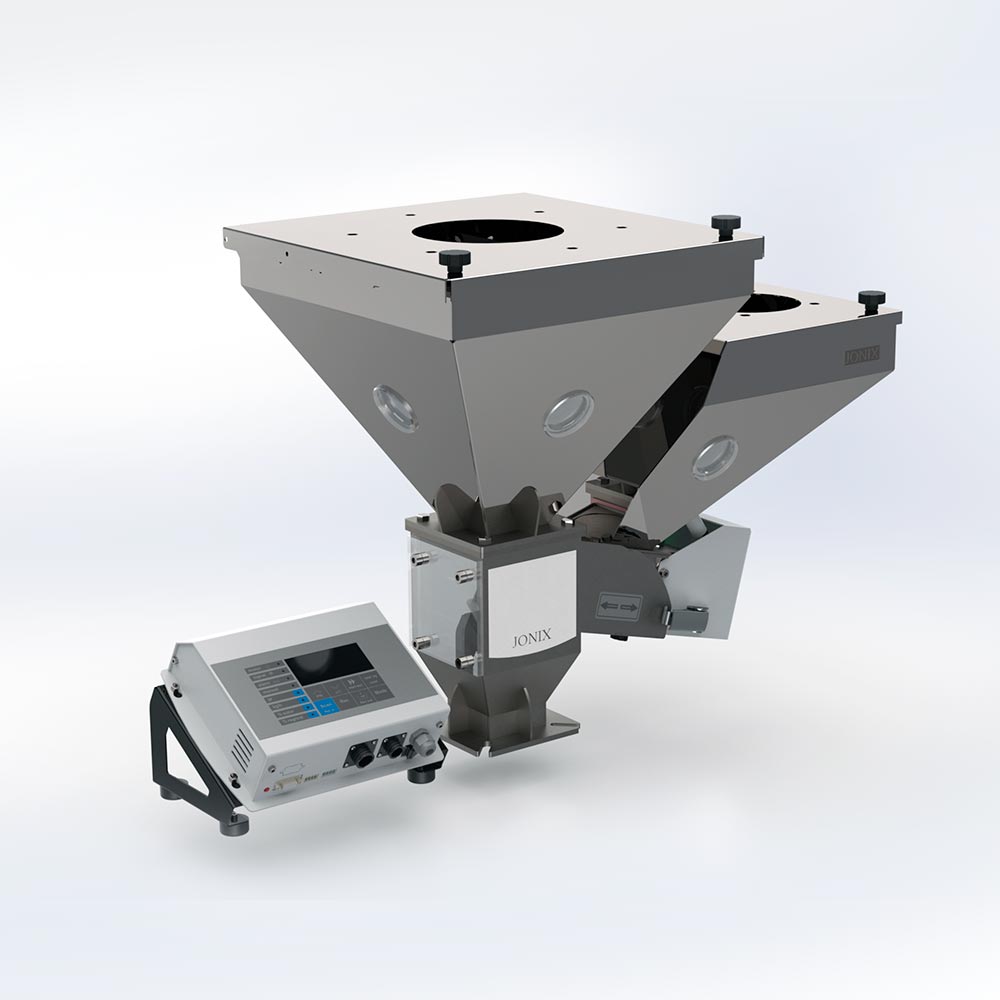

DVX volumetric feeders are designed to dose plastic pellets materials, masterbatch or other additives, in injection molding machines, extruders and blowers.

• Stainless steel construction

• Easy and accurate operation

• Automatic dosing speed calculation

• Stepper motor, no maintanance

• Saves material, blending directly into the machine

• Quick color changing process

• Hopper level sensor and audible alarm

• Totalization of material consumption

Categories

Dosing

Features

In the most common application, it is mounted directly to the machine throat by adding dyes, or additives to the main material flow. The dosers are made of stainless steel.

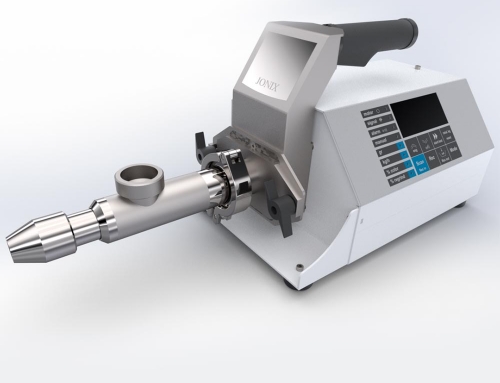

A stepper motor allows a controlled speed and maintenance free operation, no coals or brushes to change. This is complemented by the electronic microprocessor-based controller, with which in a standard way you can modify the operating mode of the dispenser. Time base for the rate and dosage times are ruled by a crystal which ensures uniformity of operation.

Total material consumption calculation determines the quantity of master or additive consumed since the last reset.

The digital controller is equipped with as standard acoustic alarm and RS485 serial output which allows different feeders to be communicate in network.

By changing the dosing screw a wide range of dosing rates can be achieved according to the need. This change can be done in minutes. Each screw is made of polished stainless steel. The tilted design of these screws provides accurate dosing.

DVX series dosers have a static mixer that allows homogenize the mixture that enters in the machine. An unique design allows cleaning the doser in a very simply way and operate in calibration mode.

Feeder hopper comes equipped as standard with a level sensor which causes an alarm on the controller, giving a flashing signal light in the dosing unit, notifying the operator to refill the unit..