Project Description

Features

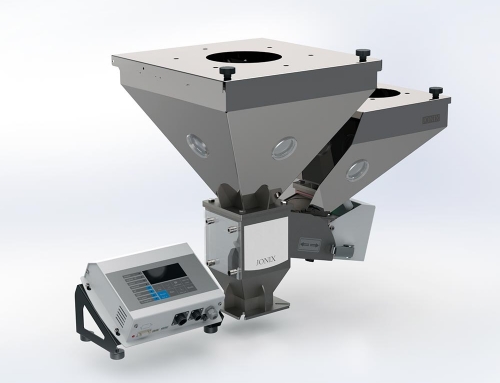

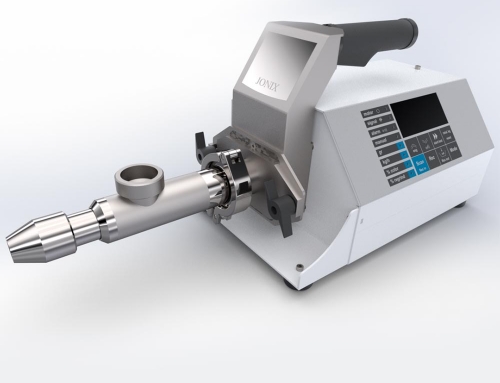

DLX liquid dispensers are designed to the precise dispense of dye, additives and other liquids with accuracy.

• Easy and accurate operation

• Automatic dosing speed calculation

• Stainless steel construction of parts in contact with the material

• Compact design

• Stepper motor

• Totalization of material consumption

• Audible and visual alarm

Categories

Dosing

Features

DLX liquid dispensers are designed to dispense with accuracy masterbatch or other liquid additives, in injection molding machines, extruders and blowers.

In the most common application, It is mounted directly to the throat of the machine by adding dyes, or additives to the main material flow. The dosers are made of stainless steel.

A stepper motor allows a controlled speed and maintenance free operation, no coals or brushes to change. This is complemented by the electronic control , with which in a standard way you can modify the operating mode of the dispenser. Time base for the rate and dosage times are ruled by a crystal which ensures uniformity of operation.

Total material consumption calculation determines the quantity of master or additive consumed since the last reset. The digital controller is equipped with standard acoustic alarm and RS485 output, which allows the doser to communicate over the network..