Project Description

Features

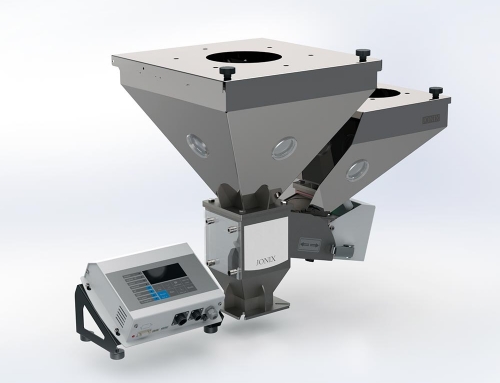

DGX gravimetric blenders are designed to dose plastic pellets, masterbatch or other additives with precision in injection molding machines, extruders and blowers.

• Stainless steel construction

• Easy and accurate operation, selection of percentages

• Automatic dosing recalibration

• Totalization of material consumption

• Touch screen panel 7″ included

• Direct installation in machine or dosage unit

• Ready for Industry 4.0

Categories

Dosing

Features

DGX gravimetric blenders are designed to dose plastic pellets materials, masterbatch or other additives, in injection molding machines, extruders and blowers. They use the batching system (dosing in batches). All materials to be mixed are weighed into the weigh hopper. Each material is dosed separately using pneumatic valves. When the recipe is complete the batch is transferred to the mixer where the mixture is homogenised and ready to enter into the machine. A sensor level controls the start of a new cycle.

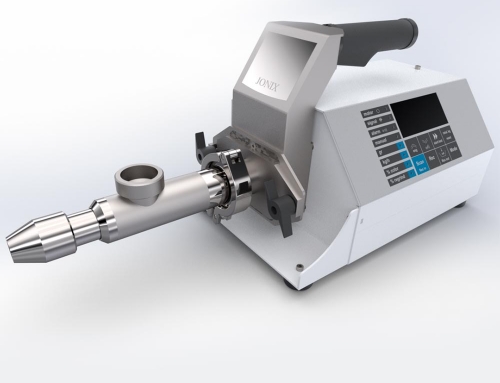

The remote control panel allows you to enter the recipe in a simple way in order to get the desired blend. Reduced dimensions facilitate mounting in the production machine. The controller operates with a microprocessor that continuously monitors batches, allowing dosage autocalibration. They have also an RS485 serial output that allows blenders to communicate over network. The total consumption feature determines the quantity of material consumed since the last reset.

Dosers are equipped as standard with a light signal and acoustic alarm giving notice of the need of re-charging hopper. Dosers can be mounted directly on the processing machine or as a central blending unit. Its stainless steel construction provides increased resistance to wear and ensure non-contamination of materials.