Project Description

Description

The S8000 hot runner controller combines the latest PC and touch screen technology together with the distributed zone control system, giving the power of graphic control at the human-machine interface in a friendly and simple way

• Designed for hot runner controller

• Touch screen ( CT )

• Integrated Industrial PC

• Simple to operate

• Autonomous Control Modules

• External alarm indicator

• Load current measurement

• Leakage Current Monitoring

Categories

Dosing

Features

In a very simple way and with the touch of a finger on the screen you can: Select the control zones to change, load or save parameters molds in the memory, display images or report events.

The control console can be separated from the cabinet for mounting convenience.

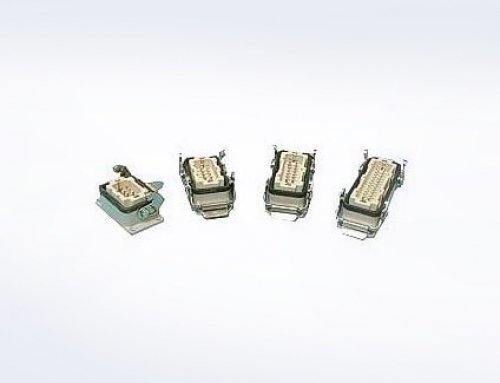

The control system of each zone is carried out by the 850C control modules located inside the cabinet. These motherboards use microprocessor technology allowing them quick adjustments and operating autonomy. These receive the information from the computer set point and the rest of the adjustments are made automatically, they can even work without alterations if they are disconnected from the console. Each plate monitors the process temperature, the charging current and the leakage current grounding resistors. The modules 850C has soft-start, parameter autotuning, automatic compensation in case of breakage of the sensor, Load restraint, automatic and manual control mode, and the standard version handle 15 A load. Its quick extraction facilitates maintenance operations and also gives the team modularity.

The cabinet is available in different configurations. It comes with general cut key, phase indicator, internal connection terminal block and quick change system power. Connectors and ventilation filters are located in the rear door. The S8000 controller has built-in wheels with brakes for industrial use.