Project Description

Description

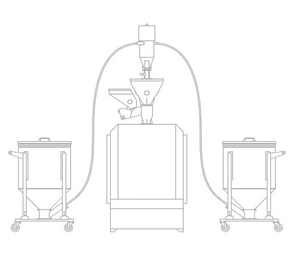

The AVX-MIX compressed air feeder transfers two materials from containers to a hopper or directly to the transformer machine automatically, in a simple and silent way.

• Percentage Mixing ratio is digitally adjustable

• Easy change material

• Minimizes material usage machine (Just in Time)

• Low maintenance with no moving parts

• Stainless steel construction

• Low noise emission

• Electronic alarm system

• Visualization of the flow of material

Categories

Conveying

Features

The mixing ratio of the materials is set digitally in the control panel by microprocessor. Using the keyboard is also possible to adjust the operating parameters of the feeder.

The materials are transferred through the suction tubes using compressed air which is applied to the venturis air amplifiers. The air flow causes the material to be dragged from the container to the separator hopper through the flexible tubes. The separator hopper uses cyclone effect to separate conveyed material from the air stream. The transparent tube allows visualizing the flow and level of material existing. Feeder control incorporates an alarm system for cutting air after a certain time from the activation of the solenoid valves.

Because it does not use electric motor does not require brush changes. Stainless steel construction minimizes contamination of the material. The feeder is supplied complete with filter regulator, suction tubes, and antistatic hose.